http://www.technologyreview.com/view/521651/graphene-supercapacitors-ready-for-electric-vehicle-energy-storage-say-korean-engineers/

Conventional batteries take so long to charge that they cannot efficiently store braking energy. But now graphene supercapacitors that store almost as much but charge in just 16 seconds could do the job instead.

Electric vehicles are coming, ready or not. And one of the enabling technologies that is making them more driver friendly is the humble battery, particularly lithium-ion versions which can store enough energy to give these cars a reasonable range for city driving.

Of course, car makers are always searching for ways to improve the efficiency, and therefore the range, of these vehicles. And one way to do this is to recover and reuse the energy that would normally be wasted when the brakes slow down a vehicle.

There is a problem doing this with conventional batteries, however. Braking occurs over timescales measured in seconds but that’s much too fast for batteries which generally take many hours to charge. So car makers have to find other ways to store this energy.

One of the more promising is to use supercapacitors because they can charge quickly and then discharge the energy just as fast. Indeed, many car makers are experimenting with just this technology.

But supercapacitors are not yet ready for the open road. That’s because, although they charge and discharge quickly, they do not store much energy.

What’s more, they tend to wear out with repeated use as the materials inside them break down with the constant flow of charge in and out of their structure. That’s is a significant drawback in a device that would have to be used many millions of times over a car’s life time.

Now Santhakumar Kannappan at the Gwangju Institute of Science and Technology in Korea and a few pals say they have a solution based on the wonder material of the moment–graphene. These guys have built high-performance supercapacitors out of graphene that store almost as much energy as a lithium-ion battery, can charge and discharge in seconds and maintain all this over many tens of thousands of charging cycles.

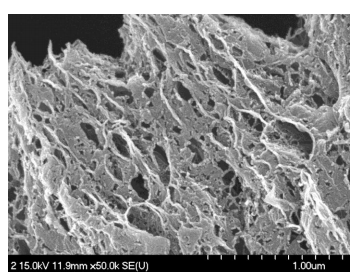

The trick these guys have perfected is to make a highly porous form of graphene that has a huge internal surface area. They create this graphene by reducing graphene oxide particles with hydrazine in water agitated with ultrasound.

The graphene powder is then packed into a coin-shaped cell, and dried at 140 degrees C and at a pressure of 300/kg/cm for five hours.

The resulting graphene electrode is highly porous. A single gram of this stuff has a surface area bigger than a basketball court. That’s important because it allows the electrode to accomodate much more electrolyte (an ionic liquid called EBIMF 1 M). And this ultimately determines the amount of charge the supercapacitor can hold.

Kannappan and co have measured the performance of their supercapacitor and are clearly impressed with the results. They say it has a specific capacitance of over 150 Farrads per gram can store energy at a density of more than 64 Watt hours per kilogram at a current density of 5 Amps per gram.

That’s almost comparable with lithium-ion batteries which have an energy density of between 100 and 200 Watt hours per kilogram.

These supercapacitors have other advantages too. Kannappan and co say they can fully charge them in just 16 seconds and have repeated this some ten thousand times without a significant reduction in capacitance. “These values are the highest so far reported in the literature,” they say.

That’s an impressive set of performance figures, which may well justify the conclusion of the authors that these “supercapacitor energy storage devices…can be scaled up for manufacturing in the near future for electric vehicle applications.”

If they’re right, we may soon see ordinary road-going electric vehicles that can efficiently harvest energy that until now has been largely wasted.

Ref: arxiv.org/abs/1311.1548: Graphene based Supercapacitors with Improved Specific Capacitance and Fast Charging Time at High Current Density

No comments:

Post a Comment